SUJI PRO

The development of Suji’s recently launched hardware.

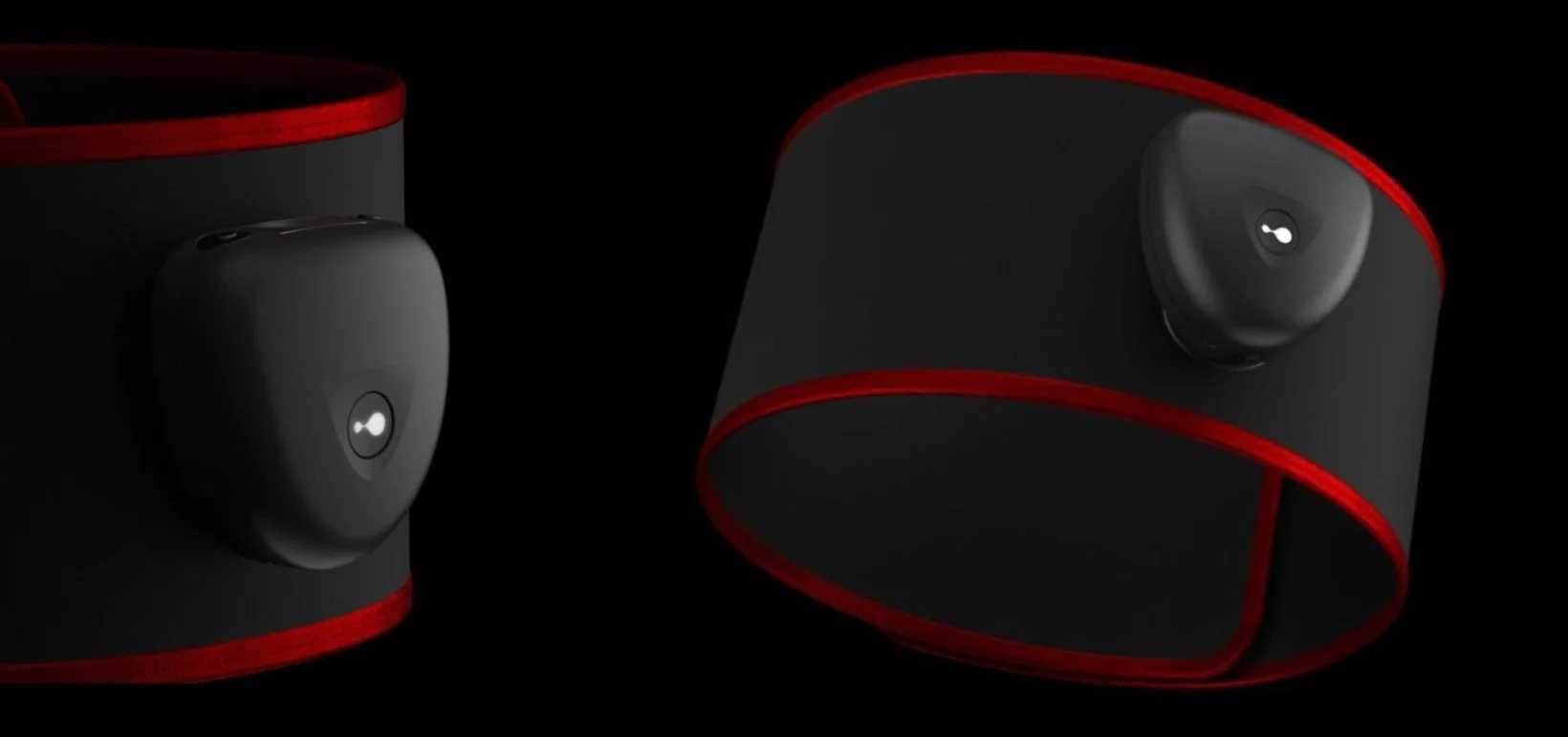

AIM: design a REMOVABLE pump AND cuff system for blood flow restriction training.

EARLY CONCEPTs

Early explorative sketches, looking at possible forms and shapes for the pump module, Early on, I realised there would be an advantage to having a non symmetrical shape as it would allow the user to quickly ascertain which direction to mount the pump in.

mood board of existing products

I looked at a range of existing products for inspiration on shape, form and elements such as surface detail and methods of joining parts together.

SKETCHING TYPICAL USER WORKFLOW

I like to sketch workflows out to visualise how the user interacts with a product and to identify any issues they are experiencing. The workflow here shows how users tended to interact with an older version of BFR which required wires and was less streamlined.

DEVELOPED SKETCHEs

I mocked up basic CAD to use as an underlay and created a range of concepts by sketching over the underlay. I explored the option of having a “bumper” type piece on the cuff to house the pump but after testing early mock ups and speaking to users, I decided to proceed with having the pump mounted directly to the cuff.

MOCK UPS

After mocking up concepts by hand with modelling clay and epoxies, I experimented with a range of block 3D prints to test different connection methods and mechanisms. After a lot of iteration, I decided to go for a magnetic connection combined with a friction fit to create an air tight seal.

The pump Can be removed from the cuff for charging and storage. Pressures within the cuff can reach 1 Bar during exercise, so the connection mechanism had to able to withsTAND this. This PARt of the design required a lot of testing and iteration.

FUNCTIONAL TESTS

Until this point, I had been focused on how to connect the pump to the cuff, and had not considered how to stack the parts and layers within the cuff so that it could withstand the necessary pressures. It was not an option to have the dock for the pump moulded into the cuff as the tooling cost was astronomical. I tested lots of options including snap fits, rivets, making changes to the geometry and eventually came up with a solution that worked.

PACKAGING DESIGN

To improve customer experience and create a premium “unboxing” experience, I designed and ordered custom packaging for the Suji Pro. This involved researching suppliers and different manufacturing techniques to ensure we ended up with a quality result.

TRANSFER TO MANUFACTURE

One of my favourite parts of this project was building the relationship with our contract manufacturer and working with them to finalise the design and improve the assembly process. I had the opportunity to travel out to Indonesia twice to work on the line with their engineers.

I PROJECT MANAGED THE ENTIRE PROJECT, THIS INVOLVED WORKING WITH STAKEHOLDERS ACROSS EUROPE, ASIA AND AMERICA to manufacture and launch the product on time.

PRODUCT LAUNCH

The Suji Pro officially launched in February this year and more info can be found here.